Ultrasonic Sensor FAQ: Detection Range and Accuracy

To choose the right ultrasonic sensor for a particular application, it is necessary to determine which factors affect the detection range and accuracy of ultrasonic sensors and how incorrect measurements can be corrected.

1. what factors influence the range of ultrasonic sensors?

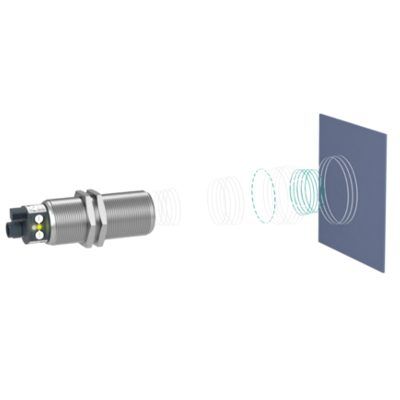

The surface properties and the angle of attack of an object have an influence on the range of an ultrasonic sensor. The highest range is achieved by a flat surface (standard reflector), which is exactly at right angles to the sensor axis. For very small objects or objects that partially “reflect” the sound away, the range is reduced accordingly. For objects with a smooth surface, the 90° angle of incidence must be maintained as accurately as possible. If the object has a rough surface structure, the angle can deviate correspondingly further. Dust and high humidity also attenuate the sound waves in the air. However, since the ultrasonic sensors from Pepperl+Fuchs are equipped with large functional reserves, this circumstance hardly affects the range.

The maximum detection range is achieved with a flat surface (standard reflector) that is exactly at right angles to the sensor axis.

2. What Factors Influence the Sound Cone of an Ultrasonic Sensor?

The detection behavior and response curve of a sound cone are shown in curves. These curves show the area from which a particular object can be reliably detected. The reflection properties of an object are primarily responsible for the response curve. Objects with a large surface area and optimal orientation (large sound cone) are more easily detected than small, round objects or objects with poor reflective properties (small sound cone).

3. Can the sound lobe be modified using software?

4. How Does Ultrasound Behave in Overpressure Conditions?

The speed of sound decreases by less than 1 % between sea level and 3000 m altitude. Atmospheric fluctuations at a specific location are also negligibly low and the effects on the speed of sound are scarcely measurable. If an application involves overpressure of more than 1 bar compared to standard pressure, the speed of sound increases while air damping decreases. This means that ultrasonic sensors have an increased detection range in the case of overpressure compared to standard pressure conditions. From overpressure of around 3 bar above standard pressure, parameter settings in the sensors must be changed so that the increased detection range and lower air damping do not cause interference and measurement errors.

Safety Notice:

In installation situations with overpressure, it is important to note that most standard ultrasonic sensors are not designed to be installed with just their front in the pressure range when the rest of the sensor is outside the pressure range. Special models are available for these installation situations. However, installing standard models completely in the overpressure area is not a problem. Only the information above regarding possible parameter adjustments at higher pressures must be considered.

5. What Does Accuracy Mean for Ultrasonic Sensors?

Accuracy or absolute accuracy is the difference between the measured value output by the ultrasonic sensor and the actual measurement distance. When using ultrasonic proximity switches in industrial work areas from -25 °C to +70 °C, absolute accuracy of 1 % – 3 % is realistic. If the ambient conditions are constant, higher accuracies can be achieved. In this case, it is advisable to switch off the temperature compensation function in the programming tool. Another option is to use an ultrasonic reference sensor. This involves mounting a second sensor of the same type parallel to the measuring sensor and aligning it to a fixed object. If ambient conditions in the measuring range change, the distance to the object will also change due to the altered speed of sound. To avoid this error, the measured value of the measuring sensor must be corrected, e.g., in the controller.

From a practical point of view, absolute accuracies of 1-3% are realistic for the industrial use of ultrasonic proximity switches in the operating range from -25°C to +70°C.

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.